How It's Done:

KWIK STAND BOW STAND

How It's Done: Making the Kwik Stand Bow Stand

By Grainger Editorial Staff 3/26/24

Founded in 1959, Du-Bro Products and Pine Ridge© Archery is a family business headquartered in Wauconda, Illinois.

“The types of products we make here at Du-Bro Products and Pine Ridge Archery are specialty products, whether it be hardware, fasteners, or accessories for multiple industries, but more specifically for archery and fishing hobby and sport said Brian Bychowski, president and owner of the company. "We make a lot of injection-molded products, metal products, and all kinds of different gadgets and gizmos that help people enjoy their hobbies.”

One of the company’s popular gadgets is the Kwik Stand Bow Stand. An idea born of necessity, the stand is used by archers either in the field or during target practice to keep a bow upright so it doesn’t come in contact with the ground and dirt. Brian said it's common for customers to discover a need and communicate that need to the team at Du-Bro Products. "We hear a lot of, ‘Hey, you need to make this,’ or, ‘Hey, this is out there but it's not good and we need something better.’" he said. "We'll hit the drawing board and get with our designers and come up with an idea or a product that will make that situation easier for that customer.” Marketing Specialist Brian Schiller walks through the steps of making the Kwik Stand Bow Stand in their factory.

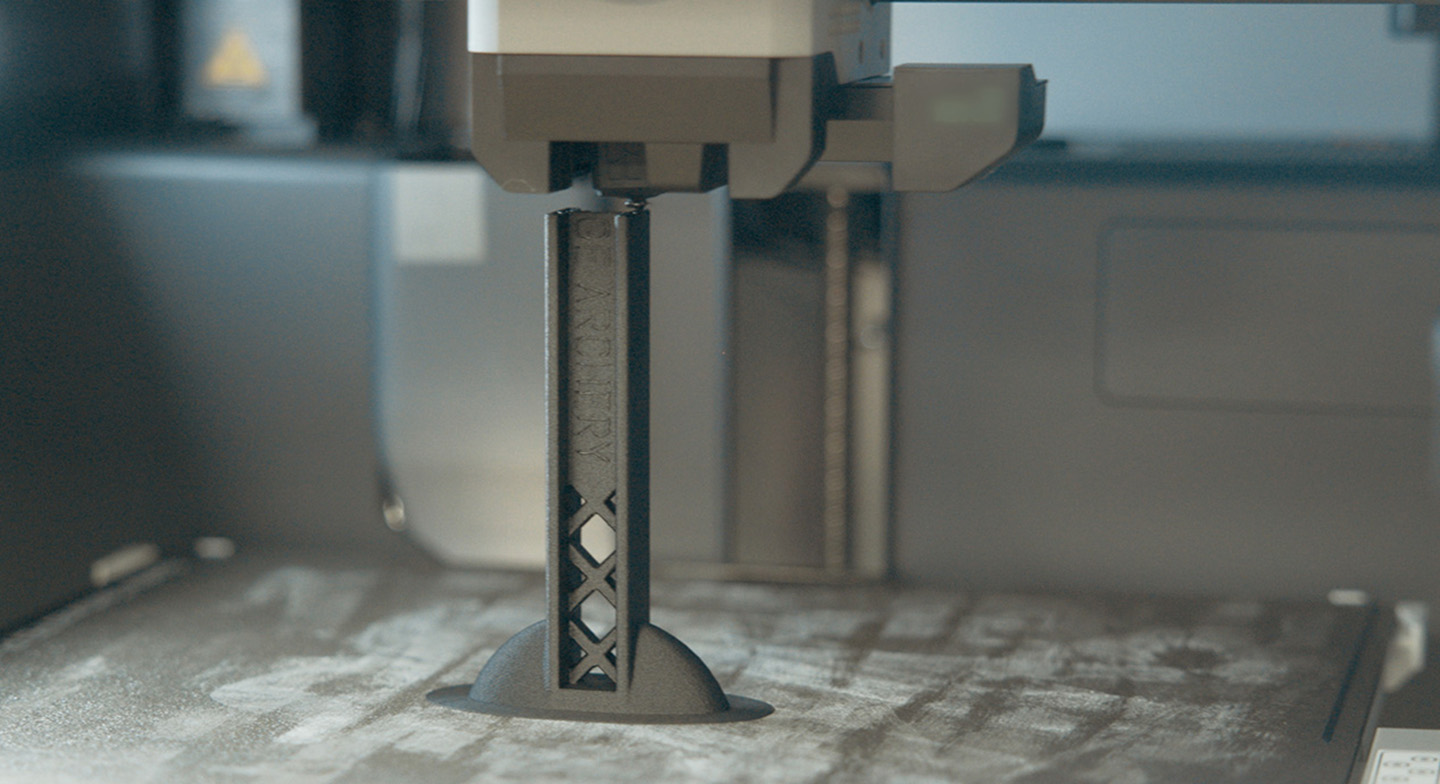

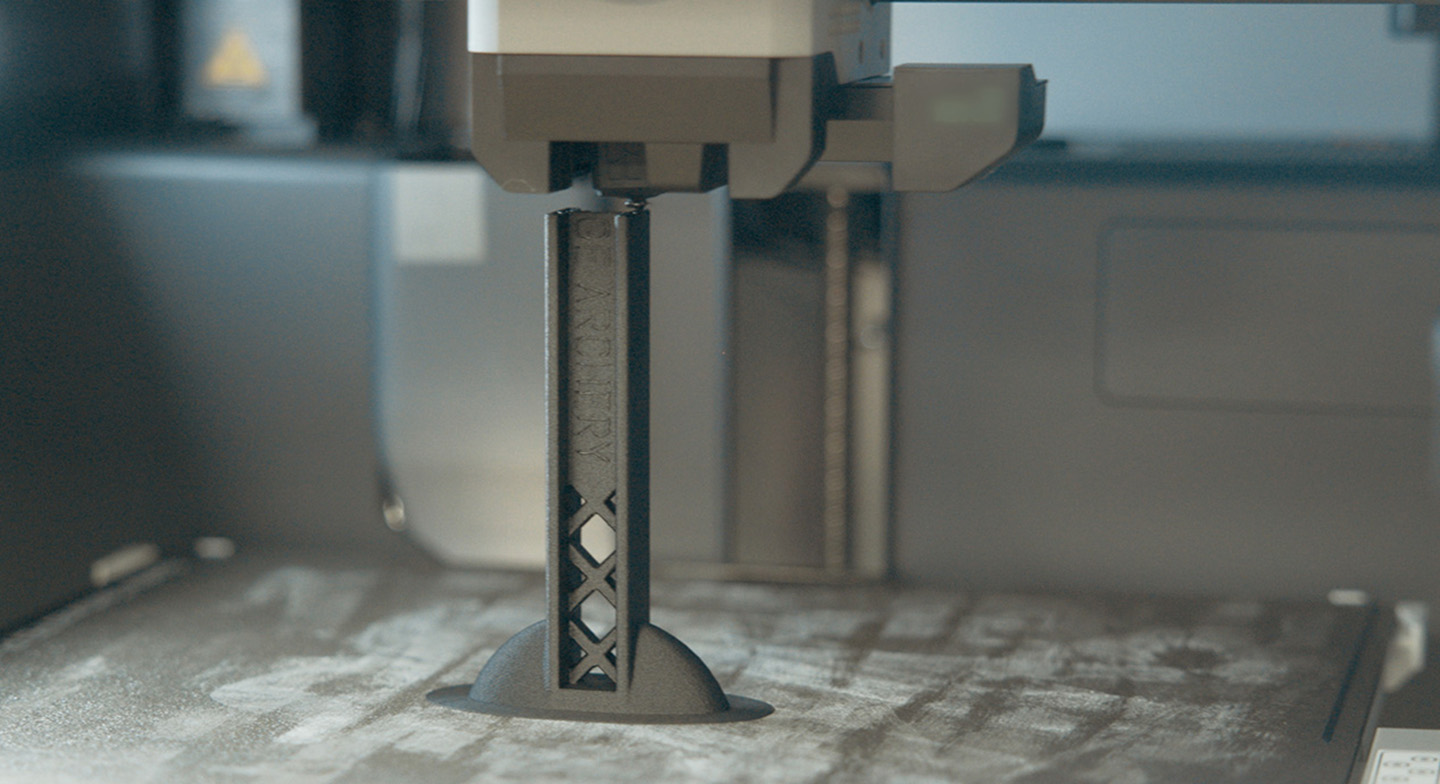

1. CAD Design

The first step is coming up with a concept and then taking that idea to the drawing board to create a computer-aided design (CAD). This is accomplished with software to draw a 3D model of the proposed product design. Once the 3D drawing is complete, it’s sent to a 3D printer to create a prototype of the final product.

2. Field Testing

Field testing is done to make sure the prototype of the product performs exactly as intended, and that it can hold up to everyday use. Field testing, Brian said, is the best way to ensure “you're getting a product that's going to last as long as possible, through as much abuse as you can give it.”

3. Making the Mold

After field testing, a hardened-steel mold is created from the prototype. Once complete, the steel mold is ready for the plastic. Each plastic component of the stand will come out of one of these molds. When the parts are ready, the pieces are taken out for trimming and assembly.

4. Parts Trimming

After the parts come out of the injection mold, they have what’s known as a runner, or excess material, which needs to be trimmed off. This is done by hand, using either a sharp utility knife or scissors. This step helps ensure the parts are clean, consistent and free from any imperfections.

5. Assembly

The Kwik Stand Bow Stand has many parts, including the jaws, legs and leg extensions, and each is molded separately. Once they’ve all been trimmed and inspected, the product is assembled by hand.

6. Packaging

After the bow stand is assembled, it is packaged in a custom-made clam shell with a header card that explains what the product is and how to use it. Once packaging is complete, the product is stored in the warehouse until it gets sent out for distribution to retailers and consumers.

With the advent of CAD and 3D printers, creating and developing gadgets like those manufactured at Du-Bro Products is much more streamlined. While each of these steps can vary in complexity depending on the end product, it’s easy to recognize how today’s advanced technologies have made it much easier and more cost-effective to conceptualize, draw, create and test a new product all in one location.

“We like to have our product displayed nice and unique on a shelf or a stand. We have an actual cutout clam shell that was custom made for our Kwik Stand. The package includes a header card that explains what the product is both front and back, and how to use the product. The card cinches in place and then it's ready to go up on the shelf and out to our distributors, retailers, or consumers.”

—Brian Schiller

Find out how Du-Bro Products makes their Trac-A-Rod for storing and transporting fishing rods.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.