How It's Done:

NEON SIGNS

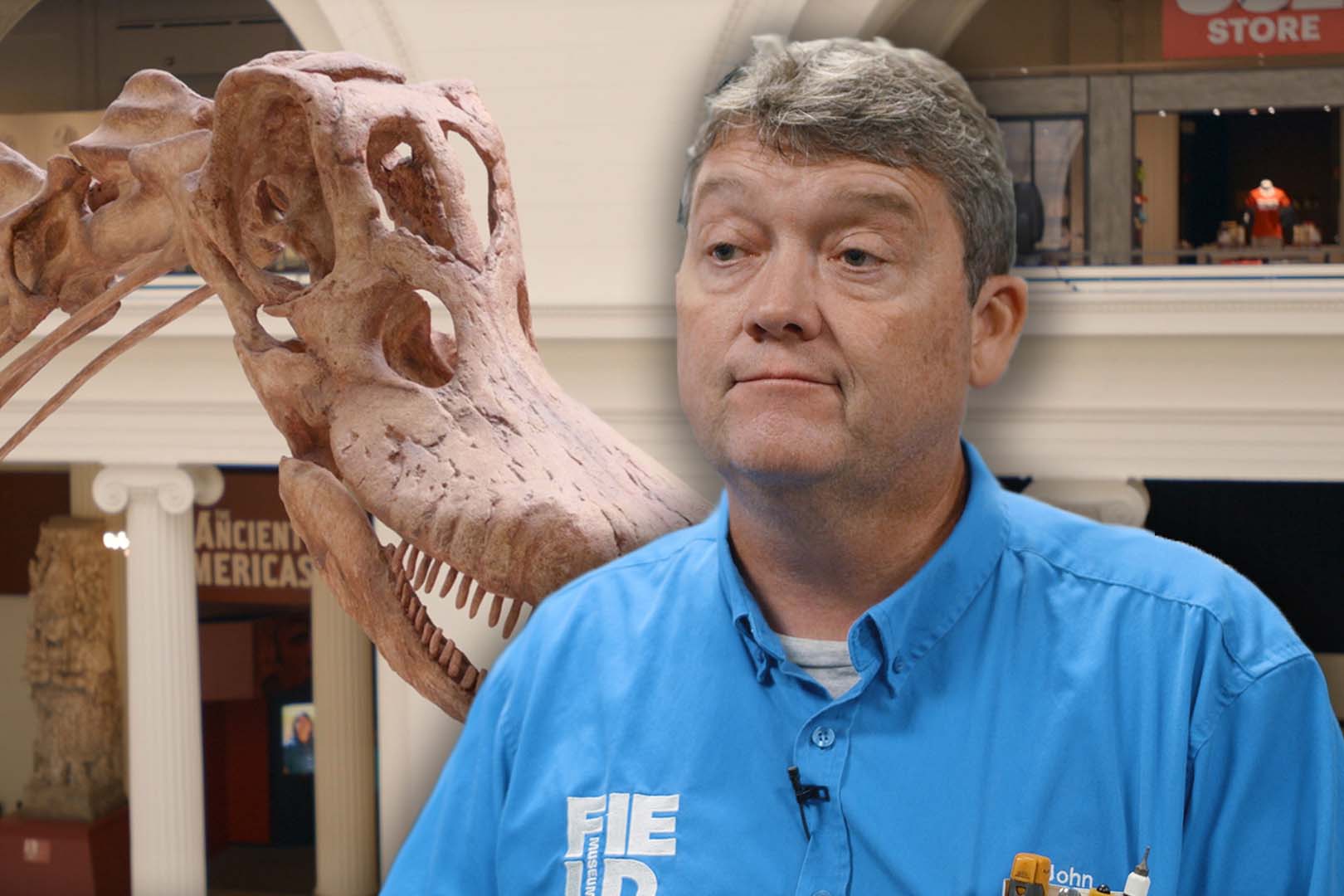

Grainger Everyday Heroes: Field Museum Engineer

By Grainger Editorial Staff 1/29/20

John Phillips may never personally touch any of the dinosaur fossils, rare gemstones or ancient mummies that fill the Field Museum’s exhibit halls, but as the Chicago museum’s Lead Engineer, Phillips is responsible for preserving the priceless collection.

“My end of caring for our artifacts is simply producing the right environment for their preservation,” he says. “Maintaining the right humidity and temperature levels, that’s my end of it.”

Although most of his work takes place behind the scenes, John knows that future generations of visitors depend on his success.

“If we lose an artifact, whole generations will never see it,” he says. “Kids coming up will never even know it existed. So it's our job in engineering to control these spaces and keep these artifacts maintained for generations to come.”

Of course, maintaining the climate in the exhibition halls is important for the Field Museum’s visitors, as well. “I want our guests to be comfortable, too,” Phillips says. “If it gets hot and steamy inside in the summer, neither I nor anyone else would want to come in.”

Tending the “Heart” of the Museum

For over 25 years, Phillips and his team of engineers have kept the “heart” of the Field Museum pumping. “We call the central plant the heart of the museum,” he says, as he walks through a long subterranean room. Its walls are lined with a maze of brightly labeled pipes connecting a long row of pumps, heat exchangers, boilers and chillers. “And all the piping going out, those are the building’s arteries. All the chill water pipes, the steam lines, the hot water loops and domestic water pipes running throughout the building—those are the arteries that feed this building.” He points up at the pipes disappearing into the ceiling. “That's how we maintain the artifacts: that chill water loop, that steam loop.”

The museum’s central plant is unusual in its size and complexity. “Our building was constructed in 1921,” Phillips says, “And it's a very complicated building with lots of equipment. Over the years, we’ve added new chillers, new boilers and new pumps: domestic water pumps, fire pumps, new circulating pumps for heating and cooling.” The end result is a system “that’s much more complex than what you would find in, say, a standard school or office building in the Chicago area.”

Staying In Control

John’s day starts with a team meeting at 6:30 a.m., when he reviews the day’s goals with his six-member engineering team. “We go through what we want to accomplish, then split up for rounds.”

While half the team is out inspecting the building’s central plant and plumbing, Phillips starts tackling the day’s work orders. “We rely on a Q-ware system to manage our maintenance scheduling,” he says. “So, for example, every three months, we’re going to service the air handlers.” The software provides his team with the day’s agenda. “And then we go from there.”

Digital controls help John’s team maintain conditions inside the gallery. “The main thing helping us regulate these exhibit spaces is our Building Automation System. The computer controls the air handlers through our set points, so I can go into the system and see exactly what each air handler is doing. It shows me the temperature and humidity levels, letting me know that the space is right for the exhibits and comfortable for our guests. I want everyone to have a nice experience at the museum.”

Thriving Under Pressure

Keeping the museum’s artifacts safe is a high stakes job, but Phillips is drawn to the challenge. “I've never dreaded coming to work,” he says. “Where else do you have mummies? You're not gonna have them over in an office building. We’ve got dinosaur bones, ancient canoes, Greek statues. Beautiful things that have to be preserved for the future.”

And it’s the future that inspires his work. “Every part of this building, there's something I did, something that's going to last years beyond when I'm gone,” he said. “That’s how I see it.”

![]()

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.