How It's Done:

Baseball Field to Football

How It's Done: Converting a Baseball Field to Football

By Grainger Editorial Staff 3/6/22

Defined by bright summer sunshine and the bold green, brown and white tapestry of the diamond, Chicago’s Wrigley Field has hosted professional baseball for more than a century.

But an entire generation of sports fans may not know that professional football was played annually in Wrigley Field from 1921-70. The games were not played until the Cubs had wrapped up for the season in September and lasted well into the cold of December.

The geometry of playing football on a plot made for baseball – and an oddly shaped one at that – might not be ideal. Wrigley Field’s football layout in its professional heyday ran north-to-south, between the left field wall to first-base dugout. An unforgiving brick wall awaited players just 18 inches beyond the northeast corner of the end zone, while the south end zone was a half-yard shorter than regulation, to avoid going into a baseball dugout.

Football rarely appeared at Wrigley Field once the pro team departed in 1970, but the old problems didn’t disappear. For a college football game in 2010, the configuration put the back of one end zone just feet from a brick wall, leading officials to have all offensive play go the same direction, away from the wall.

Anthony Spatafora, facilities specialist for the Chicago Cubs, said he and his colleagues worked hard to solve this geometry puzzle when preparing Wrigley Field to host a college football game for the first time in 11 years, in fall 2021.

Some lessons had been learned during conversions for concerts and other events in the intervening years, such as where power could be installed or how field walls could be removed. Still, a football field had yet to find a comfortable setting within Wrigley Field. Spatafora and team accepted the challenge.

“Over the year, we went and actually shot lasers at the entire ballpark, figuring out what our field grade is, what are we going to use to be able to get a full football field to run east to west,” he said.

“We actually put in thousands of different points into a 3D map to be able to really see how the field was going to orient to the inch. How, if we tilt it a little bit more on this side, would we get a little more distance on the sideline?”

What his team used, ultimately, was the Cubs’ dugout. Surrounding structures were dismantled, foam and scaffolding filled the remaining sunken area and sod was laid on top to provide an end zone along with a buffer for the players to run safely out the back.

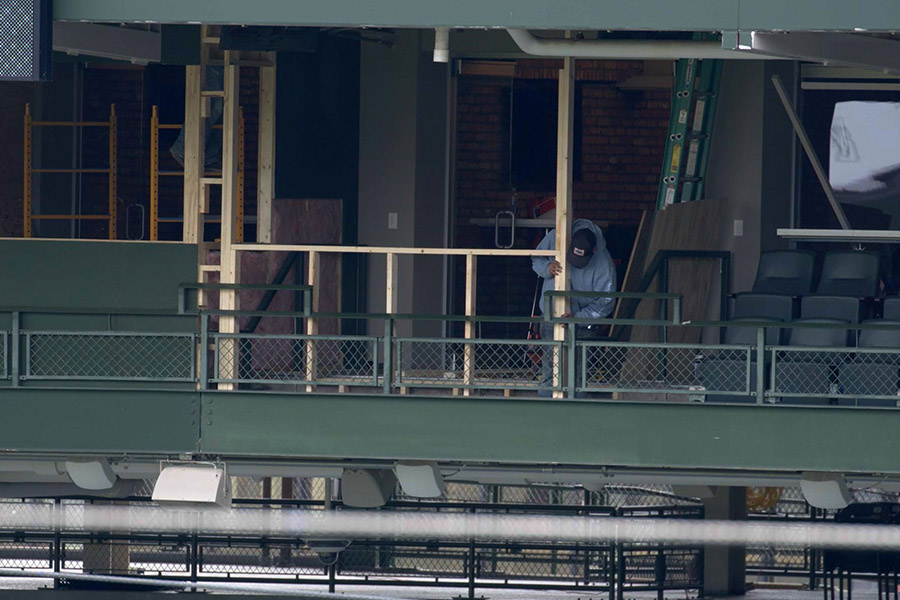

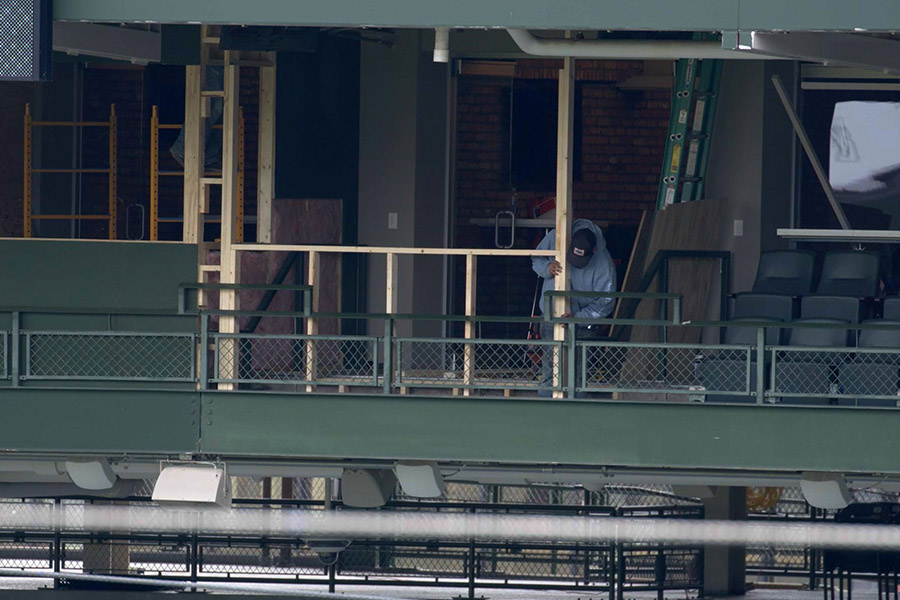

The conversion challenges were not limited to field fit. Crews pulled up the entire baseball playing surface and replaced it with a new grass football surface. Two suites, selected for their location and angle to the field, were transformed into coaches’ boxes with sliding glass windows and heat. Nets built to restrain foul balls were adapted to catch field goals. Spatafora said there were carpenters, laborers, electricians, plumbers and other trades, many doing work a little outside their comfort zone.

“It was a great experience to be able to put, 'installing goal posts in Wrigley Field’ on your resume,” he said.

“Once the lines and the field markers and the logos and stuff were out there, we'd stand at the 50-yard line with the guys that we worked alongside with to really take it all in, before the fans were there,” Spatafora said. “That was a really great moment that we were able to kind of share together. No one but that group can really say that.”

Overall, the conversion took about four months. More than 31,000 fans shared the results of their efforts on a sunny, seasonal afternoon in November. Within a couple of months, Wrigley Field was converted back to a baseball park, ready to survive what was left of the winter on the shores of Lake Michigan. Spatafora and his team, meanwhile, came away with lessons they can apply the next time they are asked to make the magic happen.

“Over the past six weeks or so, we've really looked at how can we improve?” he said. “How can we compartmentalize things? What can we change? What can we change operationally? What for next time is going to make this process go quicker? We hope that we can … really make the process seamless so it's just, ‘Hey, we're converting into a football field,’ and it kind of just goes, there's no figuring it out, everything's kind of pre-made.”

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.