Blast Media Chart

By Grainger Editorial Staff 8/7/18

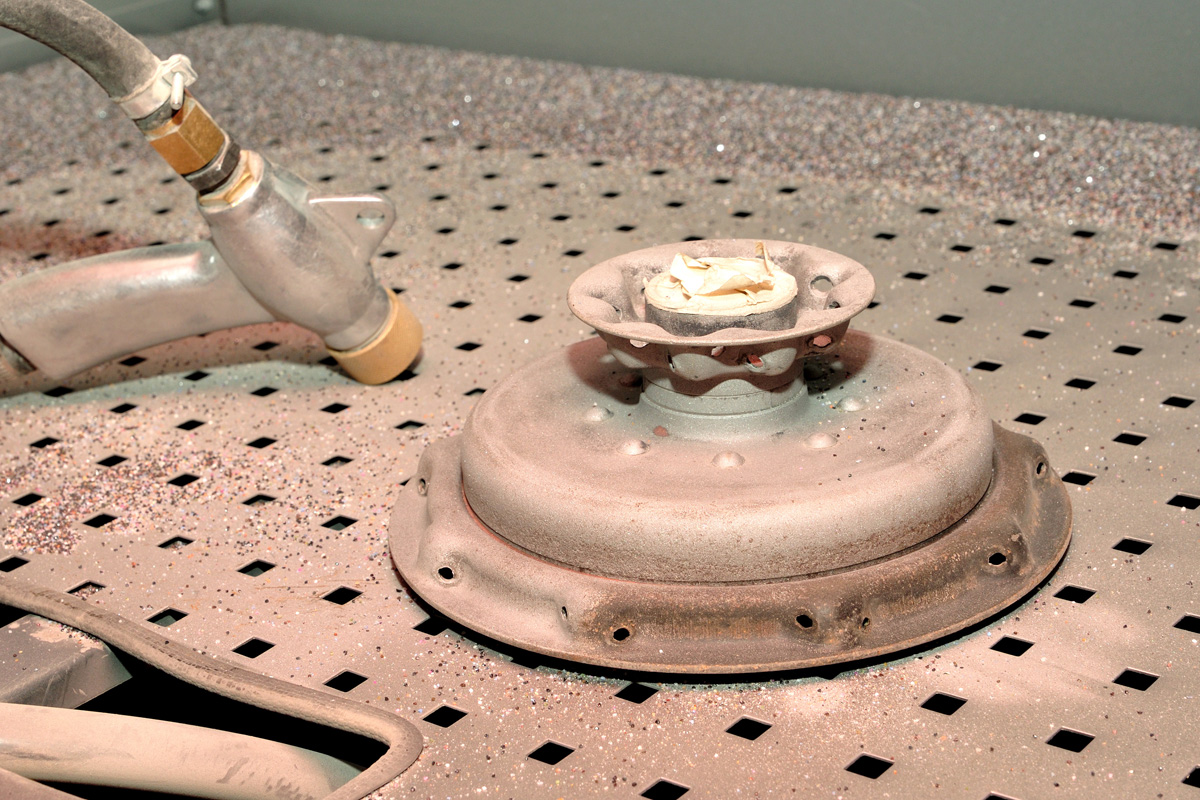

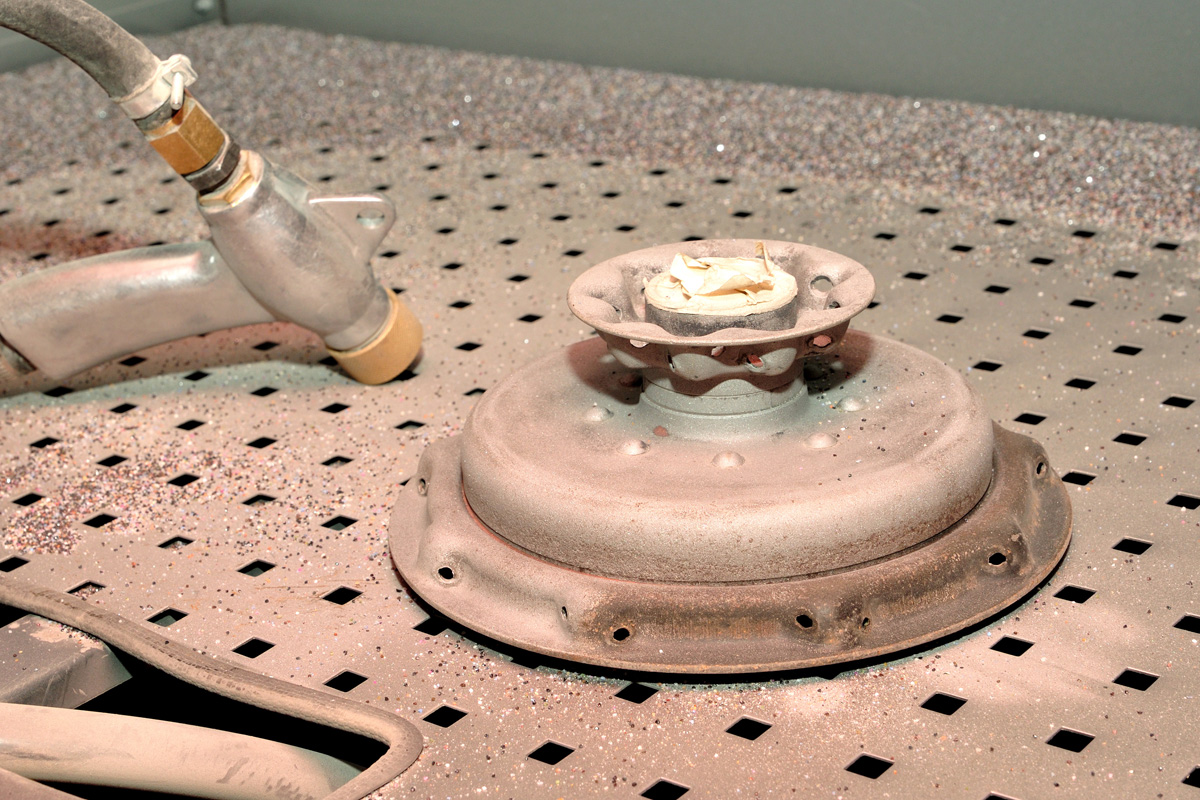

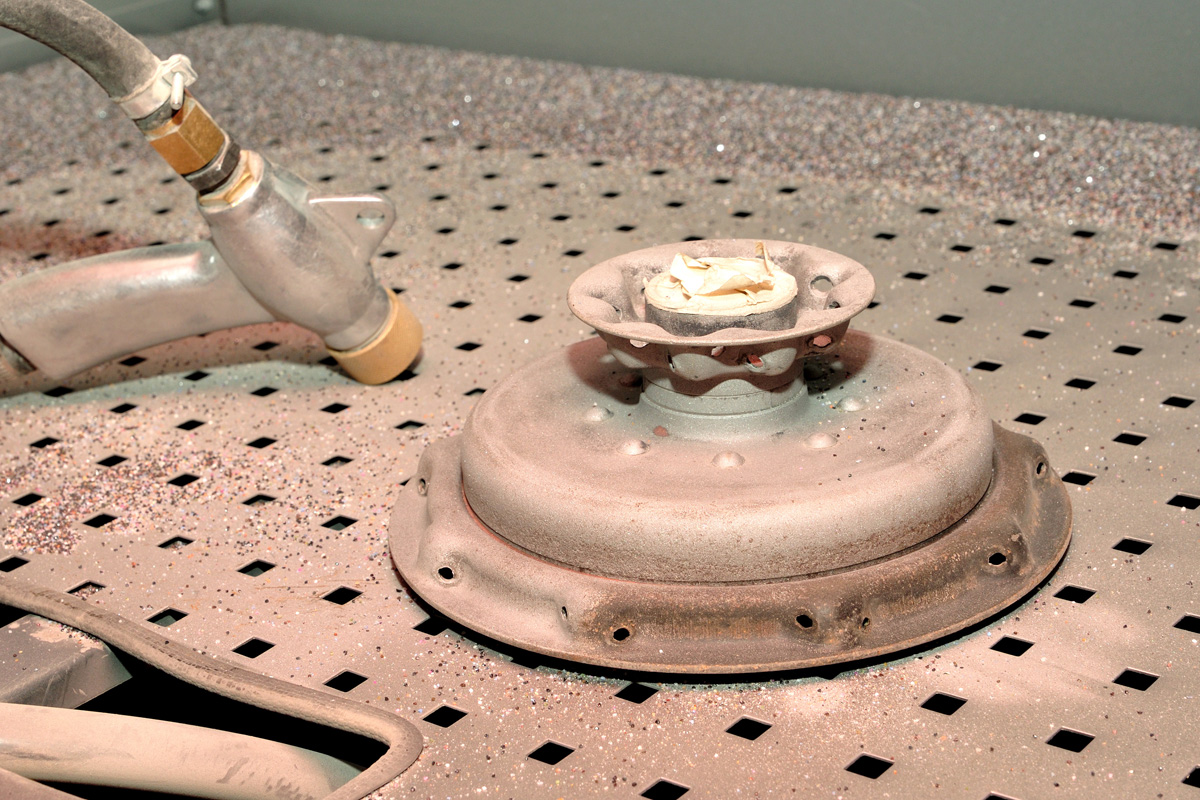

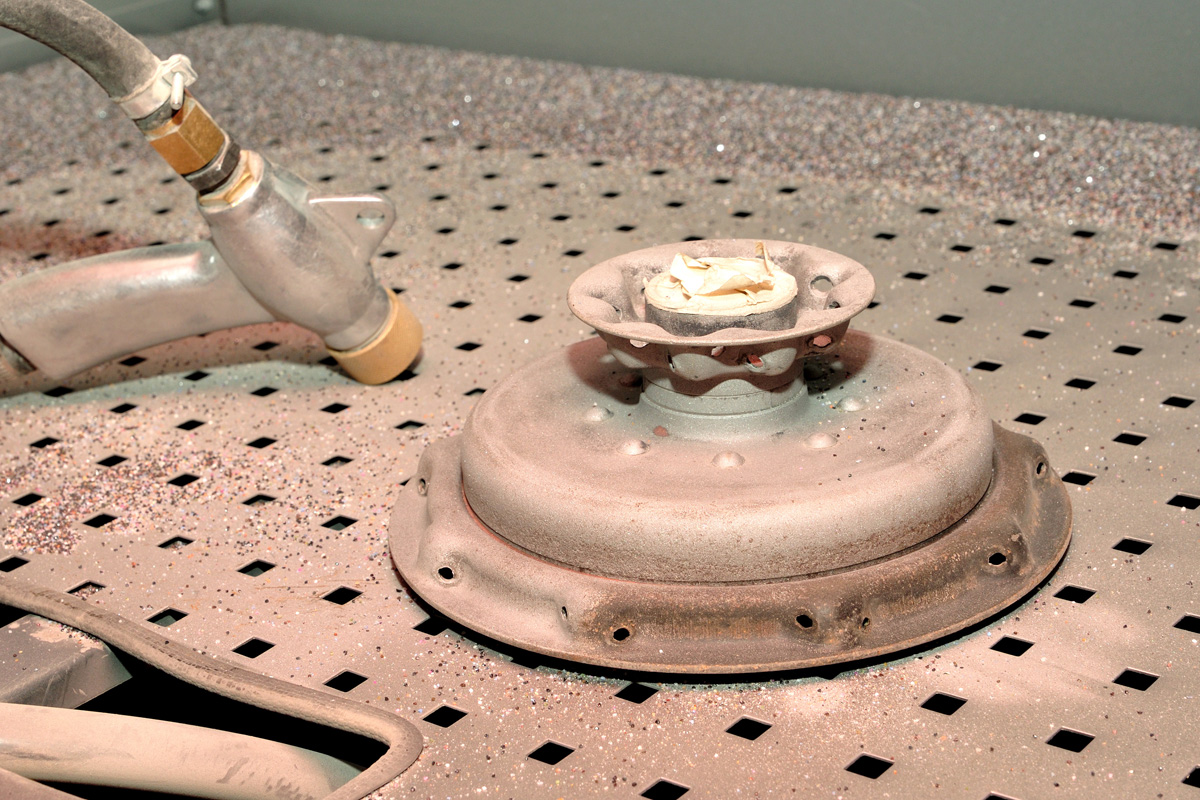

With some surfaces, a simple cleaning solution just won't do. Media blasting (also called sandblasting or abrasive blasting) has many uses, from removing a layer of paint to deodorizing molded wood beams to removing soot and fire damage. With the right high-pressured system and the right abrasive, this process can produce the end result you need.

Soft vs. Hard Abrasives

Softer abrasives are often better for cleaning, because they can remove dirt and grime with minimal effect on the material beneath. This is especially desirable if you're cleaning relatively soft or delicate surfaces like wood, plastic or machinery.

Hard abrasives remove material more quickly and can be used to create a surface profile, which is a texture of shallow indentations that helps iron, steel and other hard surfaces more easily accept protective coatings. Harder abrasives work faster and create a deeper surface profile. In general, the depth of the surface profile should be at least one quarter of the thickness of the coating you intend to put over it.

Abrasive Shape

Angular abrasives work more quickly and create a crisper surface profile. Round abrasives create a satin or peened finish and are used when no later surface coating is needed.

Abrasive Friability and Recyclability

Abrasives that break up easily into smaller pieces have high friability. Abrasives that don't break up easily have low friability and are usually recyclable. This means they can be collected and reused via a reclaiming system, usually in an enclosed cabinet.

This chart will help you understand the differences among many common types of abrasive blast media.

| Media Type | Description | Hardness | Friability | Shape | Surface Profile | Speed | Pressure | Recyclability |

|---|---|---|---|---|---|---|---|---|

|

Used for removing paint before repainting and for etching prior to recoating and plating |

9 Mohs |

Medium |

Angular |

1 mil to 16 mils |

Fast |

60 psi to 100 psi |

Medium (six to eight cycles) |

|

|

Used for removing paint before repainting and for etching prior to recoating and plating |

7 Mohs |

High |

Angular |

2 mils to 6 mils |

Medium fast |

80 psi to150 psi |

Nonrecyclable |

|

|

Used for removing oil, light coatings and surface oxidation from delicate surfaces |

4.5 Mohs |

High |

Angular |

None |

Slow |

60 psi to 150 psi |

Nonrecyclable |

|

|

Used to produce a smooth and bright finish, as well as cleaning and peening |

5.5 Mohs |

Medium |

Round |

None; satin finish |

Medium fast |

40 psi to 80 psi |

Medium (four to six cycles) |

|

|

Used for paint removal before repainting or recoating |

Used for paint removal before repainting or recoating |

Medium |

Varies |

1 mil to 6 mils |

Fast |

60 psi to 120 psi |

Low (three to four cycles) |

|

|

Used for paint removal before repainting or recoating |

5.5 Mohs |

High |

Angular |

2 mils to 6 mils |

Fast |

80 psi to 150 psi |

Nonrecyclable |

|

|

Used to prepare hard surfaces |

9.5 Mohs |

Medium |

Angular |

Very high etch |

Very fast |

60 psi to 100 psi |

Low (two to four cycles) |

|

|

Used for cleaning and paint removal |

2.5 Mohs |

High |

Angular |

None |

Medium low |

50 psi to 150 psi |

Nonrecyclable |

|

|

Used for peening, polishing and smoothing |

8 Mohs |

Low |

Round |

No etch |

Medium |

Not applicable |

High (25 to 50 cycles) |

|

|

Used for polishing and smoothing surfaces |

8 Mohs |

Low |

Round |

No etch |

Medium |

Not applicable |

High (25 to 50 cycles) |

|

|

Used for fast paint removal |

8 Mohs |

Low |

Angular |

1 mil to 6 mils |

Medium fast |

80 psi to 150 psi |

High (10 to 25 cycles) |

|

|

Used for cleaning and stripping without damage |

3.5 Mohs |

High |

Angular |

No etch |

Slow |

60 psi to 100 psi |

Nonrecyclable |

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.