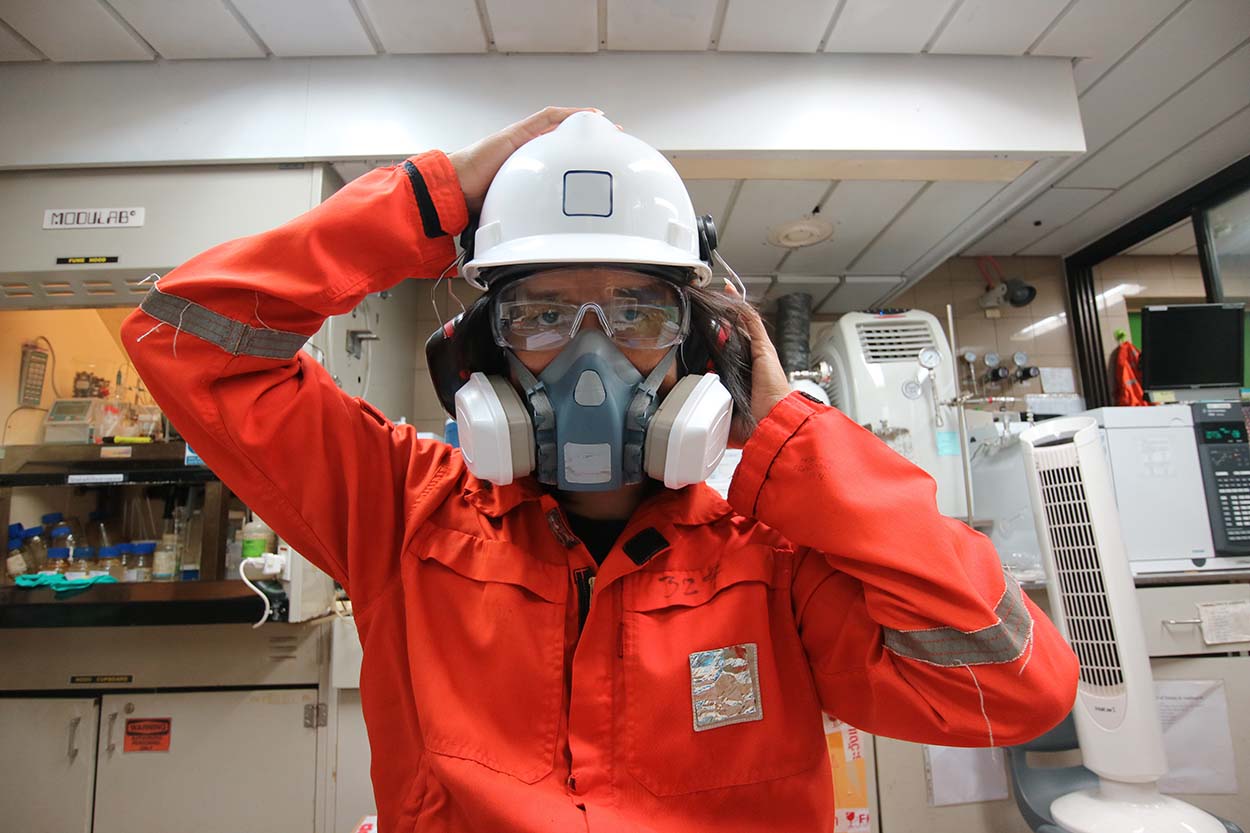

Types of Respiratory Protection Equipment

By Grainger Editorial Staff 7/1/19

Learn about types of respirators, how to create a protection program and more in this guide to respiratory PPE.

Confined spaces, dust-filled shops and other environments that could make the simple act of breathing dangerous are all in a day’s work for industrial workers. While keeping contaminants such as harmful dusts, fogs, fumes, mists, gases, smokes, sprays and/or vapors out of the air workers breathe is the first line of defense, proper respiratory protection also is essential. If re-engineering a task or equipment fails to provide a safe working environment, employers must provide appropriate respiratory protection for every employee who might be exposed to harmful contaminants.

A sound respiratory protection program

The Occupational Safety and Health Administration (OSHA) and The National Institute of Safety and Health (NIOSH) regulations define the specific requirements for respiratory protection safety compliance. Employers must follow the requirements of these governmental regulations, including the general regulations that apply to all workplaces and the specific regulations for exposures in their particular industry. Examples include lead, silica dust, asbestos and ammonia.

The seven key elements that every respiratory protection program should contain, according to program details in OSHA’s Respiratory Protection Standard (29 CFR 1910.134), are:

- A written plan detailing how the program will be administered

- A complete assessment and knowledge of respiratory hazards that will be encountered in the workplace

- Procedures and equipment to control respiratory hazards, including the use of engineering controls and work practices designed to limit or reduce employee exposures to such hazards

- Guidelines for the proper selection of appropriate respiratory protective equipment

- An employee training program covering hazard recognition, the dangers associated with respiratory hazards and proper care and use of respiratory protective equipment. Ensure fit testing occurs prior to initial use, whenever a different respirator facepiece is used and at least annually thereafter

- Inspection, maintenance and repair of respiratory protective equipment

- A medical evaluation to determine an employee’s ability to use a respirator

An additional OSHA requirement (OSHA 29 CFR 1910.1020) requires that records of medical evaluations must be retained.

Identifying Respiratory Hazards

Before a respiratory protection program is initiated, it is important to first understand the types of respiratory hazards inherent to your industry.

There are three typically recognized ways toxic materials can enter the body:

- Through the lungs (respiratory system)

- Through the skin

- Through the gastrointestinal tract

Of the three, the respiratory system presents the quickest and most direct avenue of entry. This is due to the respiratory system’s direct relationship with the circulatory system and the constant need to oxygenate tissue cells to sustain life.

There are three basic classifications of respiratory hazards:

- Oxygen-deficient air

- Particulate contaminants

- Gas and vapor contaminants

Selecting the Proper Respirator

NIOSH issues recommendations for respirator use. Industrial type approvals are in accordance to the NIOSH federal respiratory regulations 42 CFR Part 84. Selecting respirators requires knowing what level of respiratory protection employees need, as well as which size respirator is right for any face and facial contours.

Respiratory protective devices vary in design, application and protective capability. Thus, the user must assess the inhalation hazard and understand the specific use limitations of available equipment to assist in proper selection.

Respirators fall under two classifications: air-purifying and air-supplied.

- Air-purifying respirators are used against particulates, gases and vapors. These are categorized as negative-pressure respirators that use chemical cartridges and/or filters; gas masks; and positive-pressure units such as powered air-purifying respirators (PAPRs).

- Air-supplied devices rely on a primary air source to deliver a steady flow of respirable air to the user’s facepiece. These consist of Self-Contained Breathing Apparatus (SCBA) and air-line devices.

If your hazard calculation, as defined in 1910.134, shows that exposure concentrations exceed recommended limits and engineering/administrative controls do not reduce exposure below the permissible limit, you must tailor your respiratory protection program to your specific conditions:

- Toxicity (TLV, threshold limit value, or TWA, time-weighted average)

- Maximum expected concentration

- Oxygen level

- IDLH (Immediately Dangerous to Life or Health) concentration

- Warning properties (adequate or not)

- Sorbent limitations

- Facepiece fit

- Mobility requirements

- Type of use (routine, escape or emergency entry)

Air-Purifying Respirators

Air-Purifying Respirators (APRs) range from simple disposable cup masks to low-maintenance half-mask facepieces with cartridges and/or filters to the more complex PAPRs with full facepieces or hoods.

- APRs for particulates use filters to capture dusts, mists and fumes. Filters do not protect against gases or vapors, and generally become less effective as particles accumulate on the filter and plug spaces between the fibers. Filtering APRs require filter replacement when the user finds it difficult to breathe through them.

- Gas and vapor APRs employ chemical cartridges or canisters to remove hazardous gases or vapors from the air. They do not protect against airborne particles. Made to protect against specific gases or vapors, they provide protection only as long as the cartridge’s absorbing capacity is not depleted.

- Combination APRs, fitted with both particulate filters and gas/vapor cartridges, are worn in atmospheres that contain hazards of both particulates and gases.

- PAPRs provide a continuous filtered airflow with a battery-operated blower. Includes a facepiece, hood or helmet, breathing tube and a canister/cartridge/filter type assembly.

Supplied-Air Respirators

Supplied-Air Respirators (SARs) comprise air-line respirators, SCBA and combination (supplied-air) respirators.

- Air-line respirators are used for extended periods in non-IDLH atmospheres. They use a hose (air-line) to deliver clean breathing air from a stationary source of compressed air for prolonged periods of time. Although comparatively lightweight, air-line respirators can limit users’ mobility.

- Self-contained breathing apparatus (SCBA) have an open-circuit design that provides air rated for 30 to 60 minutes. They consist of a wearable, clean-air supply and a tight-fitting facepiece, and are used for short-duration (30- to 60-minute rated) work shifts and entrance to or escape from atmospheres that are or may be IDLH. They offer relatively unrestricted movement.

- Combination SARs are air-line devices used for extended work periods in atmospheres that are or may be IDLH. They have an auxiliary self-contained air cylinder that can be used if the primary air supply fails. The air cylinder can also be used for entry into or escape from IDLH atmospheres, such as confined spaces.

Employers are required to provide employees using SARs with breathing gases of high purity and ensure that compressed air, compressed oxygen, liquid air and liquid oxygen used for respiration is in accordance with the specifications of OSHA Standard 1910.134(i). Whether your inspection takes you inside a rail car to examine coatings or through a paint shop, make sure you’re wearing the appropriate respiratory protection.

Source: MSA

![]()

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.